In the entire city, our company is best known for offering best quality Chemical Coatings Services. These coatings are specially formulated for protecting the chemical processing equipment and machines from corrosion and highly aggressive conditions. It is best known for its maximum working temperature. Provide a smooth finish on the all types of material surfaces, th00000ese Chemical Coating Services ensure surface finish that is highly resistant to wear and abrasions.

Advantages:

- Economical rates

- Ideal for pipes and their fittings

- FDA approved coating

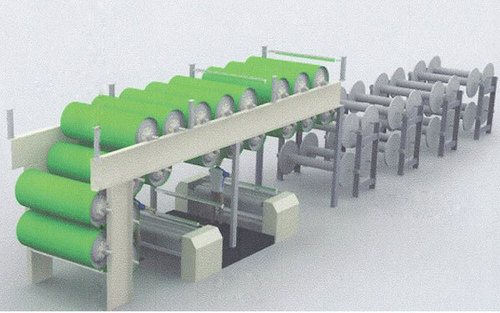

In todays world Chemical, Pharmaceutical and Biotechnology plants are looking for High product purity, Anti-Corrosion, Easy cleaning of process equipment, durability and low maintenance. To meet these demands, industry needs the plant machineries like process piping, fittings, valves, Filters, Storage Tanks, Instruments, Centrifuge basket, Vessels, Agitators etc. to be coated with various fluoropolymers like TEFLOON PFA, TEFZELETFE and HALARECTFE which offers unmatched chemical resistance, durability, non-stick surface, non-contamination of metal, FDA Approval etc. which traditional stainless steel, mild steel and glass no longer deliver.