Offshore Coatings

Product Details:

- Adhesive Side Single Side

- Feature Corrosion resistance, UV resistant

- Adhesive Strength High

- Coverage Area 8-10 m2/L at 50 micron DFT

- Max Temperature(Degree Celcius) 120C

- Thickness 200-500 micron DFT

- Size 20 L pack

- Click to View more

X

Offshore Coatings Product Specifications

- 8-10 m2/L at 50 micron DFT

- 120C

- 200-500 micron DFT

- Epoxy resin based

- 20 L pack

- Liquid

- Grey

- Brush, Roller, Spray

- Single Side

- 99%

- Industrial

- Corrosion resistance, UV resistant

- High

- Protection of offshore structures

Product Description

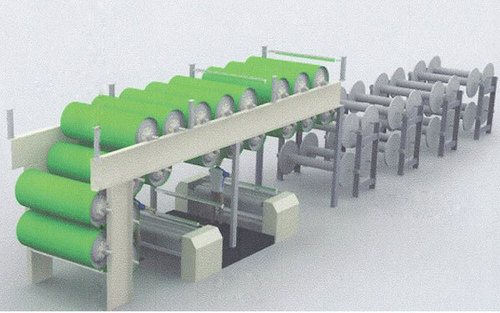

We are renowned in this industry for offering the best stock of Offshore Coating service. These coatings are extensively used for mobiles rigs, fixed platforms, pipelines, subsea structures, drill ships and floating production units. These Offshore Coating serviceprotect the structures from highly corrosive chemicals, adverse environment elements and abrasion.

Key points:

- Help reduce the impact of fast explosion of fire

- Easily applied

- Do not wear off

Our high performance coatings are reliable solution and protect offshore installation from corrosion and help to reduce impact of fast explosion of fire.

Offshore Coatings:

- TEFLOON PFA

- TEFZEL ETFE

- RILSAN

- FBE

Coatings can be used in following offshore installations.

- Floating Production Units

- Fixed Platforms

- Mobiles Rigs

- Drill ships

- Pipelines

- Subsea Structures

Reliable Protection for Offshore Structures

Engineered for reliability, our offshore coating provides exceptional chemical and weather resistance, ideal for steel and concrete substrates in harsh marine conditions. Its semi-gloss finish lends a professional appearance while safeguarding against UV radiation, corrosion, and extreme temperatures. Low VOC content ensures environmental safety and easier compliance with international regulations.

Fast Application and Durable Performance

Designed for efficiency, the coating is touch dry in just two hours and achieves complete cure within seven days. With high adhesive strength, the finish stays firmly bonded, minimizing maintenance intervals and ensuring long-term structural integrity. The wide application method options (brush, roller, spray) simplify installation and allow for uniform film thickness.

FAQs of Offshore Coatings:

Q: How should the surface be prepared before applying this offshore coating?

A: The substrate (steel or concrete) must be sandblasted to Sa 2.5 standard or equivalent to ensure optimal adhesion and coating performance. Removing all contaminants and providing a clean, roughened surface is crucial for maximizing corrosion protection.Q: What application methods are suitable for this epoxy resin-based coating?

A: This coating can be applied using a brush, roller, or spray. These methods allow for flexibility on industrial sites and facilitate even distribution across both steel and concrete surfaces.Q: When does the coating reach touch dry and full cure stages?

A: The coating becomes touch dry within 2 hours after application, while full curing is achieved in seven days under recommended environmental conditions. Avoid exposure to moisture or harsh environments during this period for optimal results.Q: Where should the coating be stored to maintain its shelf life?

A: To preserve its 12-month shelf life, store the product in its original sealed packaging within a cool, dry place away from direct sunlight. Proper storage prevents premature degradation and maintains application quality.Q: What are the main benefits of using this semi-gloss offshore coating?

A: The product offers excellent resistance to seawater, alkalis, chemicals, and UV light. It delivers high durability, strong adhesion, and outstanding protection against corrosion, while being environmentally safer thanks to its low VOC and non-toxic characteristics after curing.Q: Can this coating withstand high temperatures encountered offshore?

A: Yes, the finish is designed to resist temperatures up to 120C, making it suitable for offshore environments where thermal stress may be a concern.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email