Product Description

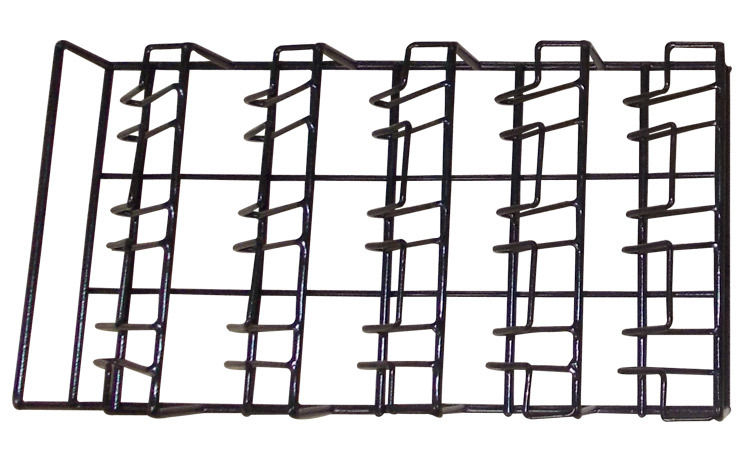

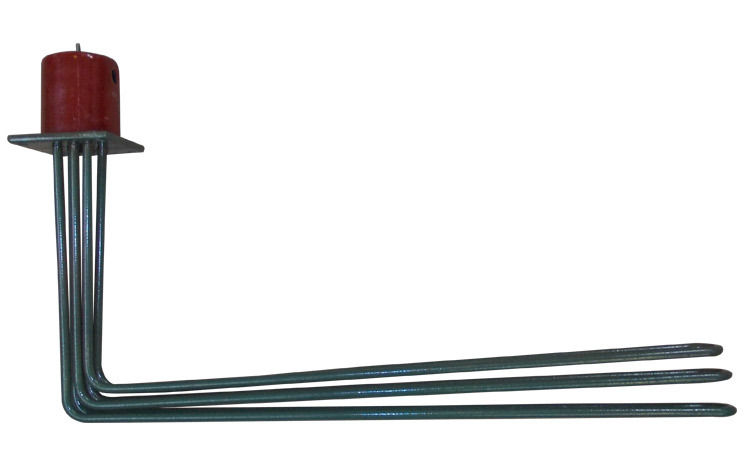

Right from our establishment in this industry, we have been engaged in offering the best stock of Anti Static Halar Coating. Dimensionally stable, this coating is formulated with superior resistance against fire. This Anti Static Halar Coating provides an extremely smooth finish on the surface of machine components. Basically a partially fluorinated semi- crystalline polymer, the coating is an excellent combination of permeation resistance.

Key points ofAnti Static Halar Coating:

- Excellent mechanical properties

- Superior thermal and chemical resistance

- Reduces the risk of pinholes in the coating

- Reduces the risk of particle accumulation on the surface

Halar ECTFE by SOLVAYis a partially fluorinated semi-crystalline polymer offering a unique combination of mechanical properties, permeation resistance, thermal & chemical resistance and versatility. Halar coatings has a very smooth surface which helps to reduce the risk of pinholes in the coating and reduce the risk of particle accumulation on the surface.

Features ofAnti Static Halar Coating:

- Dimensionally stable, Excellent fire resistance, Extremely smooth surface

- Operating temperature upto 150 deg C

- Excellent resistance to strong acids, such as sulfuric, nitric, hydrochloric and hydrofluoric

- Best radiation resistance of all fluoropolymers

- Resists strong bases, such as sodium hydroxide, that would stress crack PVDF

- Ozone-resistant, mechanically tough with excellent abrasion and impact resistance

- Available in Anti-static coating option for better static charge dissipation

Superior Industrial ProtectionThe Anti Static Halar Coating delivers unmatched protection for metallic structures, machinery, and components exposed to harsh chemicals and volatile environments. Its resistance to acids, solvents, and alkalis ensures that installations remain corrosion-free, even in outdoor or demanding industrial settings. With outstanding adhesion and smooth spray application, this coating provides a dependable shield for critical assets.

Advanced Anti-Static PerformanceUtilizing cutting-edge ECTFE polymers, this green coating keeps surface resistance below 10 Ohms, greatly reducing static electricity build-up. This property minimizes the risk of electrical sparks, making it safer for facilities where sensitive electronics or flammable materials are present. Its dielectric strength also contributes to strong electrical insulation.

Reliable Durability and Easy ApplicationWith its Shore D hardness of 75 and operating stability up to 150C, Anti Static Halar Coating stands out for durability and performance. The spray application method ensures an even, controlled finish with thicknesses ranging from 200 to 500 microns. Suitable for various substrates, especially metals, it is a premier choice for long-term industrial protection in challenging environments.

FAQs of Anti Static Halar Coating:

Q: How is Anti Static Halar Coating applied on industrial surfaces?

A: This coating is generally applied via spray coating, which allows for a controlled, even distribution of the material, creating a smooth finish with a thickness between 200 and 500 microns. Proper surface preparation and expert handling ensure excellent adhesion, particularly on metallic substrates.

Q: What benefits does Anti Static Halar Coating offer for industrial use?

A: It provides outstanding protection against corrosion from acids, solvents, and alkalis, while also offering superior anti-static and dielectric properties. Its robust adhesion, weather resistance, and high hardness make it ideal for extending the life of equipment in harsh environments.

Q: When should Anti Static Halar Coating be considered for use?

A: This coating is best used when industrial assets require both chemical and static protectionespecially in industries such as chemical processing, electronics, and outdoor facilities subject to aggressive exposure or the risk of electrical discharge.

Q: Where can Anti Static Halar Coating be used effectively?

A: It is suitable for industrial equipment, metallic structures, tanks, pipes, and machinery exposed to corrosive chemicals or outdoor elements. Its properties allow deployment in sectors like petrochemicals, manufacturing, and electronics.

Q: What is the process for ensuring optimal adhesion and finish with this coating?

A: Proper surface preparation is essential, including cleaning and possibly roughening the substrate. The ECTFE-based spray coating is then applied in controlled layers to achieve the required thickness and smooth, durable finish.

Q: How does this coating contribute to electrical safety?

A: With a surface resistance below 10 Ohms and strong dielectric strength, the coating effectively dissipates static electricity and provides insulation, reducing risks associated with electrical sparks or static build-up near sensitive or flammable materials.