3-Layer Polyethylene 3LPE Coating

Product Details:

- Application Method Extrusion coating process

- Feature High impact resistance, superior corrosion protection, long-term durability

- Coverage Area Depends on pipe length & diameter

- Size Customized as per pipe diameter

- Adhesive Side Inner adhesive layer

- Shape Cylindrical (applied on pipe surface)

- Max Temperature(Degree Celcius) 80

- Click to View more

X

3-Layer Polyethylene 3LPE Coating Price And Quantity

- 1000 Square Centimeter

3-Layer Polyethylene 3LPE Coating Product Specifications

- Polyethylene (PE), Epoxy, Adhesive

- Coating

- Depends on pipe length & diameter

- Extrusion coating process

- Pipe corrosion protection

- Pipeline External Coating

- High impact resistance, superior corrosion protection, long-term durability

- 1.8 - 3.0 mm

- Customized as per pipe diameter

- Cylindrical (applied on pipe surface)

- Inner adhesive layer

- 80

- >100 N/10mm

- 99

- Black / Grey

3-Layer Polyethylene 3LPE Coating Trade Information

- 1000 Square Centimeter Per Week

- 5 Days

Product Description

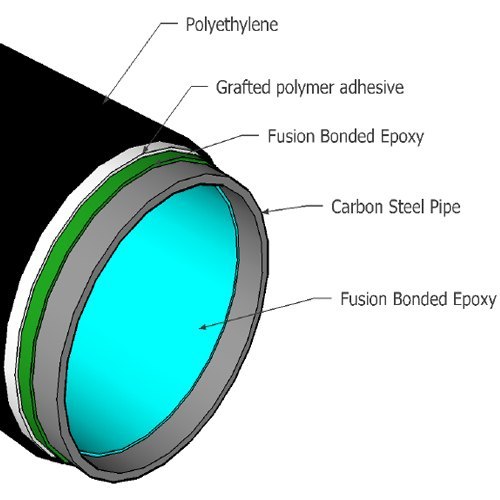

3 layer polyethylene coating is functional as a multilayer coating made of three functional mechanisms. This is made to provide excellent corrosion protection as well as advanced mechanical protection for oil & gas pipelines. This is made to attain a superior long term corrosion resistance and is accessible with outstanding mechanical protection for large as well as small diameter pipelines. 3 layer polyethylene coating can be applied well to meet several project specifications as well as requirements.

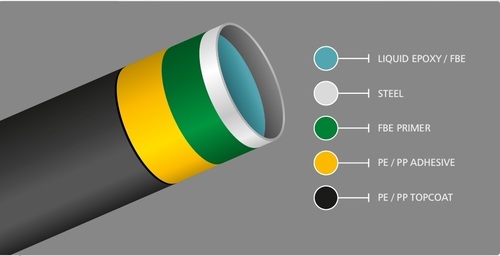

Triple-Layered Protection for Pipelines

The 3LPE coating system integrates three robust layers-Fusion Bonded Epoxy for adhesion and anti-corrosive performance, a specialized adhesive for bonding, and an outer polyethylene layer for mechanical strength. This combination offers an unmatched shield against environmental factors and physical impacts, ensuring the integrity and longevity of pipelines over decades of service.

Superior Chemical and Mechanical Resistance

Engineered to withstand aggressive chemicals like acids, alkalis, and salts, 3LPE coating maintains its protective qualities even under harsh conditions. High impact resistance and excellent peel strength, as verified by ASTM standards, protect pipes from physical stresses encountered during transportation, installation, and operation.

Optimized Application Process

Applied via precision extrusion coating, the 3LPE system achieves uniform coverage and adhesion. Customizable to any pipe diameter and available in black or grey, this coating transforms ordinary pipes into high-performing infrastructure components. Its low water absorption and exceptional UV resistance further enhance its suitability for exposed environments.

FAQ's of 3-Layer Polyethylene 3LPE Coating:

Q: How is the 3-Layer Polyethylene (3LPE) Coating applied to pipes?

A: The 3LPE coating is applied using an extrusion coating process, where a Fusion Bonded Epoxy (FBE) layer is first applied, followed by an inner adhesive, and then finished with an outer polyethylene layer. This ensures uniform coverage and strong adhesion to the pipe surface.Q: What types of pipes are compatible with 3LPE coating?

A: 3LPE coating is suitable for carbon steel, ductile iron, and alloy steel pipes, making it a versatile choice for a variety of pipeline projects in industries ranging from oil and gas to water distribution.Q: When is 3LPE coating recommended for use?

A: 3LPE coating is recommended for situations where external pipe corrosion prevention and mechanical protection are critical, especially in buried or exposed pipeline environments subject to harsh chemicals or physical impact.Q: Where is 3LPE-coated pipe typically installed?

A: 3LPE-coated pipes are commonly used in external pipeline installations, such as oil and gas transmission lines, water conveyance systems, and industrial infrastructure projects requiring long-term durability.Q: What benefits does the 3LPE coating provide over other coating systems?

A: The 3LPE system offers superior corrosion resistance, high impact strength, excellent chemical and UV resistance, and a service life exceeding 50 years under proper conditions. Its high adhesive and peel strength also prevent coating separation, adding to long-term reliability.Q: How does 3LPE coating resist chemical and environmental damage?

A: 3LPE provides exceptional protection against acids, alkalis, salts, and moisture, thanks to its multi-layered structure. Low water absorption and high dielectric strength insulate pipes from chemical attack and electrical faults.Q: What considerations are needed for sizing and coverage of 3LPE-coated pipes?

A: The coverage area depends on the pipe's length and diameter. The coating thickness ranges from 1.8 to 3.0 mm and can be customized to fit specific project requirements, ensuring optimal protection and performance.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email