3LPE Coating

400 INR/Piece

Product Details:

- Coverage Area As per pipe size

- Feature High corrosion resistance, excellent adhesion, chemical resistance

- Adhesive Side Inner epoxy & adhesive layer

- Application Method Heat fusion, extrusion coating

- Particle Size Not Applicable (Coating)

- Thickness 1.8 mm to 4.5 mm

- Max Temperature(Degree Celcius) Up to 80C continuous

- Click to View more

X

3LPE Coating Price And Quantity

- 400 INR/Piece

- 10 Square Foot

- 400.00 - 1200.00 INR/Piece

3LPE Coating Product Specifications

- Inner epoxy & adhesive layer

- 99

- Polyethylene, Epoxy, Adhesive

- High corrosion resistance, excellent adhesion, chemical resistance

- As per pipe size

- Pipeline corrosion protection

- Superior bonding strength

- Custom sizes available

- Coating

- Pipe surface

- Black

- Oil & Gas, Water Pipelines

- Up to 80C continuous

- 1.8 mm to 4.5 mm

- Not Applicable (Coating)

- Heat fusion, extrusion coating

3LPE Coating Trade Information

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cash Advance (CA)

- 1000 Square Foot Per Week

- 10 Days

- Yes

- Free samples are available

- Wooden

- Middle East, Asia

- All India

- ISO 9001:2015

Product Description

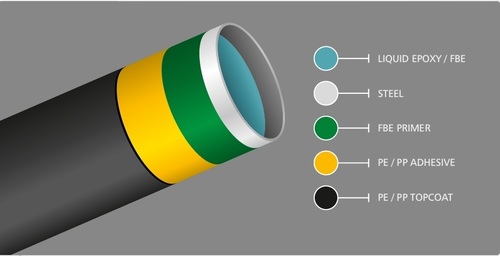

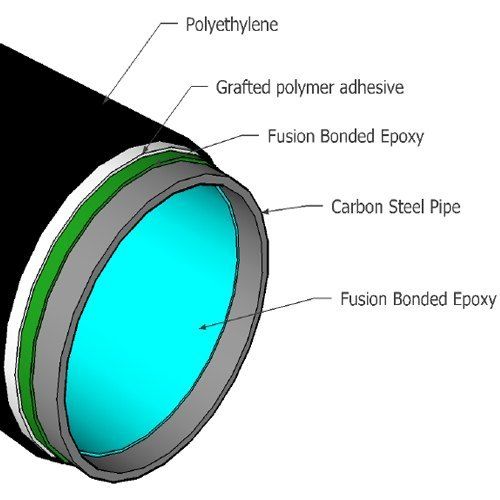

3LPE Coating refers to a coating that is multilayer and is throughly composed of three main functional units and components: It is considered to be the high performance unit that is followed by a copolymer adhesive as well as outer layer made up of polyethylene that provides tough and durable protection. The product can withstand the varied temperatures along with the environments that ranges from dessert dry lands to deep underwater regions. The product is of great benefit when it covers the steel pipes and further make them suitable to be used for taking around the drinking water, oil and gas and other fluids.

KEY POINTS:-

1) The 3LPE coating grants great endurance to withstand the high temperatures up to 60 deg Cto 80degC.

2) Product has excellent chemical and corrosion proof feature that prevents steel pipes from any kind of damage.

3) The resistivity against cathodic disbondment as well as the high performance characteristics leads to an extended life cycle.

4) Outer layer of polyethylene safeguards the physical damages towards either the pipes or the fusion bonded epoxy at the time of handling.

Long-Term Corrosion Protection

3LPE Coating is engineered to guard pipelines against corrosion for up to 50 years, utilizing a meticulous three-layered system that includes a tough polyethylene topcoat and chemically resistant epoxy base. Its adherence to ISO 21809-3 ensures reliability in a variety of environments, offering high durability for both oil & gas and water pipelines.

High Performance and Durability

This advanced coating provides outstanding impact resistance and maintains integrity even at temperatures up to 80C. Its low water absorption and excellent weather resistance means it is well-suited to harsh climates. Rigorous testing such as holiday and peel strength tests confirm the systems reliable adhesion and protective qualities.

Flexible Application and Customization

With compatibility spanning various pipe diameters and custom thicknesses (from 1.8 mm to 4.5 mm), 3LPE Coating meets diverse pipeline requirements. The coating is applied through heat fusion and extrusion methods, ensuring a seamless bond. Storage guidelines recommend keeping the material dry and shielded from direct sunlight for optimum performance.

FAQs of 3LPE Coating:

Q: How is the 3LPE coating applied to pipeline surfaces?

A: The 3LPE coating is applied through heat fusion and extrusion coating techniques, ensuring a strong bond as each layerthe epoxy primer, adhesive, and polyethylene topcoatis sequentially fused onto the pipe surface.Q: What makes 3LPE coating highly effective for corrosion protection?

A: The three-layer structure provides a robust barrier: the epoxy primer gives chemical resistance and adhesion, the intermediate adhesive ensures excellent bonding, and the polyethylene topcoat protects against mechanical damage, corrosion, and environmental stress.Q: When should 3LPE-coated pipes be used for pipeline projects?

A: 3LPE-coated pipes are ideal for new and replacement oil, gas, and water pipelines, especially where long-term corrosion protection, mechanical durability, and resistance to harsh climates are needed.Q: Where can 3LPE coating be applied?

A: This coating is suitable for pipelines in a variety of settings, including buried, underwater, or exposed environments. Its compatibility with different pipe diameters and custom sizes enables wide-ranging industrial and infrastructure use.Q: What testing ensures the quality of 3LPE coating?

A: Quality is verified using tests such as the holiday test to detect coating defects and the peel strength test to assess adhesion levels, ensuring the coatings protective effectiveness and durability.Q: How should 3LPE coating be stored before use?

A: To maintain quality, the coating or coated pipes should be stored in a dry environment and protected from direct sunlight and physical damage until application.Q: What are the main benefits of choosing 3LPE coating for pipeline systems?

A: 3LPE coating offers high corrosion and chemical resistance, superior adhesion, longevity (up to 50 years), excellent impact tolerance, and suitability for a range of temperatures and pipeline sizes.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email