- Excellent corrosion resistance

- Non-porous coating

- Coating thickness upto 1000 microns

- Good abrasion resistance

- FDA approved coating

- Operating temperature upto 260 deg C

PFA Coating Service

Product Details:

X

Product Description

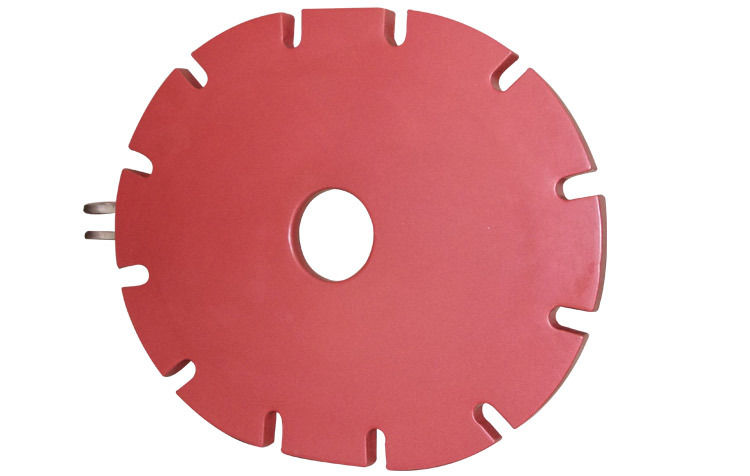

Since years, we have been engaged in offering the best stock of PFA Coatings. These coatings are highly suitable for valve components, filter housing, storage tanks and pipes & fittings. PFA Coating is applied on the components for protection against corrosion and other adverse weather conditions. Also known as per fluoro alkoxy based coatings, these coatings are best known for their high temperature resistance.

Key points ofPFA Coatings:

- Excellent ability to achieve non-porous films

- Chemical resistant surface finish

- FDA approved coatings

- Optimum friction coefficient

Features ofPFA Coatings:

Typical Components:

- Valve components

- Pipes & pipe fittings

- Filter housing

- Storage tanks

- Level indicator

- Shafts & agitators

- Centrifuge baskets

Advanced PFA Technology

Our service leverages advanced Perfluoroalkoxy polymer technology to deliver comprehensive surface protection. PFAs superior properties enable excellent chemical resistance, withstanding harsh acids, bases, and solvents, making it an ideal solution for a diverse range of industrial applications. The smooth, non-stick finish enhances workflow and equipment longevity.

Customizable Solutions for Your Needs

The PFA Coating Service offers fully customizable thickness options from 20 to 100 microns and supports both standard transparent and custom color finishes. We tailor the process based on project complexity and provide flexible order quantities, ensuring precise coatings for your unique requirements.

Reliable Service Across India

With onsite application available across India, our experienced technicians assess and process every job with efficiency. The service duration and processing time vary as per project specifications, ensuring every coating meets your schedule and quality demands. Our robust adhesion ensures long-term, maintenance-friendly performance.

FAQs of PFA Coating Service:

Q: How is the PFA coating applied to industrial surfaces?

A: The PFA coating is applied onsite by our professional technicians using specialized equipment to ensure even coverage and optimal adhesion. The application method and thickness (20-100 microns) are selected based on your specific requirements and component geometry.Q: What industries can benefit from PFA coating services?

A: A wide range of industries benefit from our PFA coatings, including chemical processing, pharmaceuticals, food processing, electronics, and more. The excellent non-stick, chemical-resistant, and dielectric properties make it suitable for critical industrial environments.Q: When should PFA coating be considered for equipment protection?

A: PFA coating is recommended whenever equipment is exposed to aggressive chemicals, high temperatures (up to 260C), or requires a smooth non-stick surface. Early application protects components from corrosion and enhances operational safety.Q: Where are your PFA coating services available?

A: Our onsite PFA coating services are available throughout India, allowing us to serve manufacturers, exporters, suppliers, and service providers nationwide. We adapt our services to your location and facility needs.Q: What is the process for customizing coating thickness and color?

A: Customization begins with a consultation to understand your performance and aesthetic needs. Depending on your requirements, we adjust the coating thickness (20100 microns) and offer custom colors beyond the standard transparent option.Q: How does PFA coating improve equipment durability and safety?

A: PFA coatings provide a chemically inert barrier with high adhesion strength, excellent dielectric insulation, and thermal resistance up to 260C. Such properties extend equipment lifespan, reduce maintenance, and enhance operational safety by preventing chemical corrosion and electrical faults.Q: What is the minimum order quantity (MOQ) and how does processing time vary?

A: The minimum order quantity is set as per your project needs, with no fixed threshold. Processing time depends on project complexity, coating thickness, and color requirements, and is finalized during the consultation phase.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email